Air Blasting Equipment

Air Blasting often called "Sandblasting"

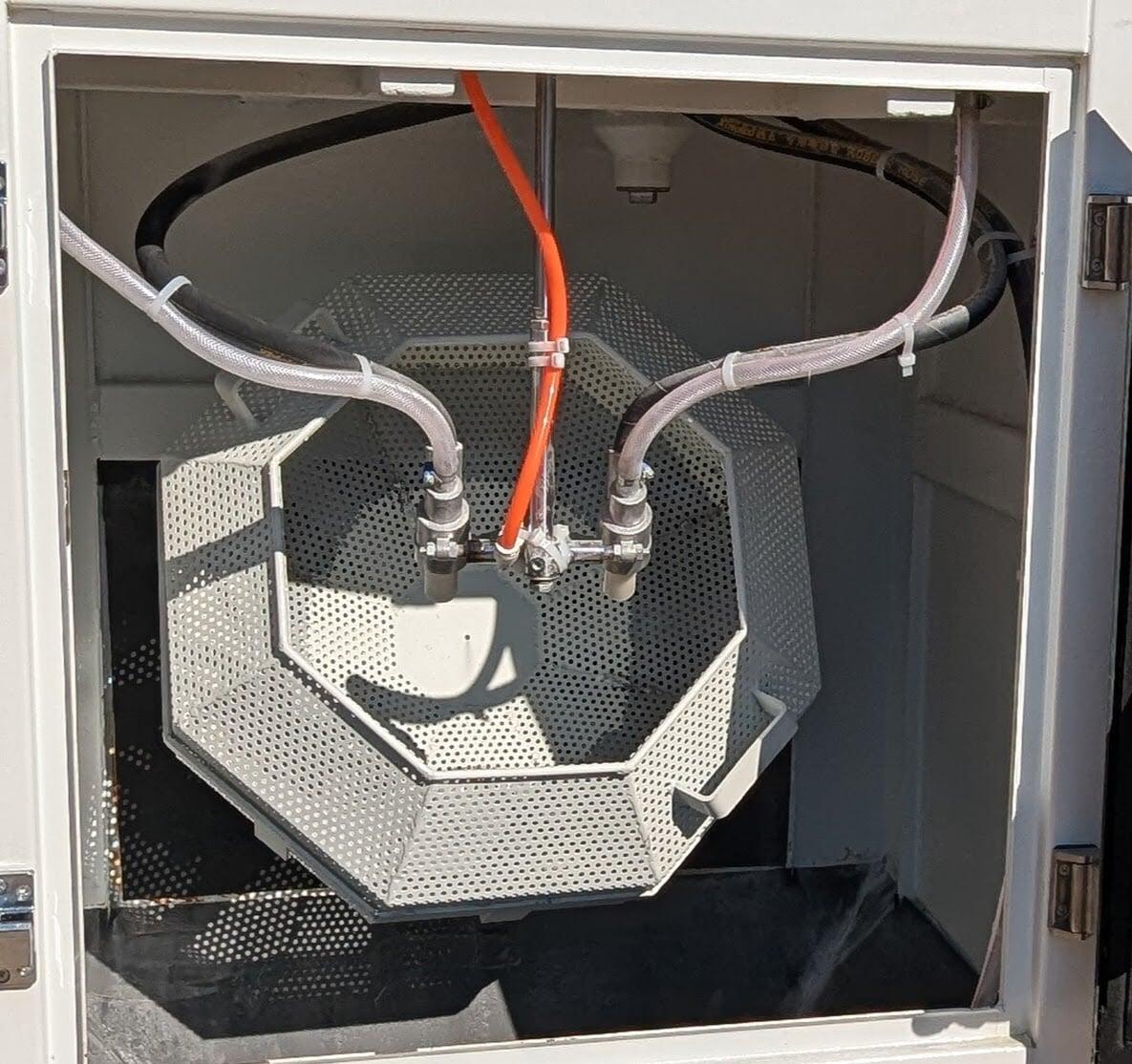

Blasting is the process where small angular or spherical particles are propelled at a part by compressed air. The blast media type, shape, size, density, and hardness, along with media acceleration and volume of media, combined with blasting distance from the workpiece, angle of impact, and time cycles are important factors in the blast process capabilities. This can be used to achieve various outcomes for the materials you’re working on.

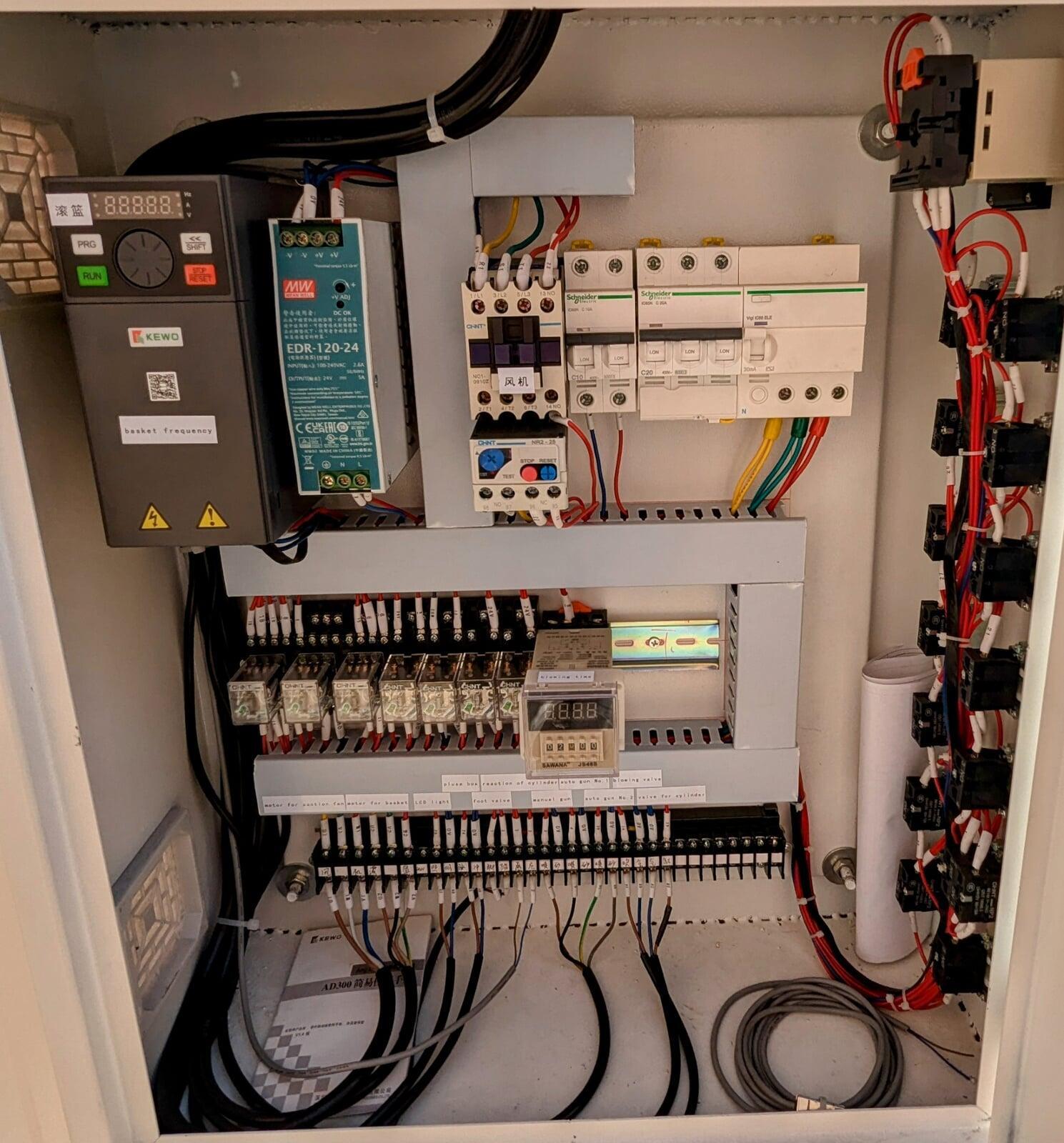

At Unified Technologies, we supply a full line of manual and automated shot blast, grit blast, and shot peening systems!

How Does Air Blasting Work?

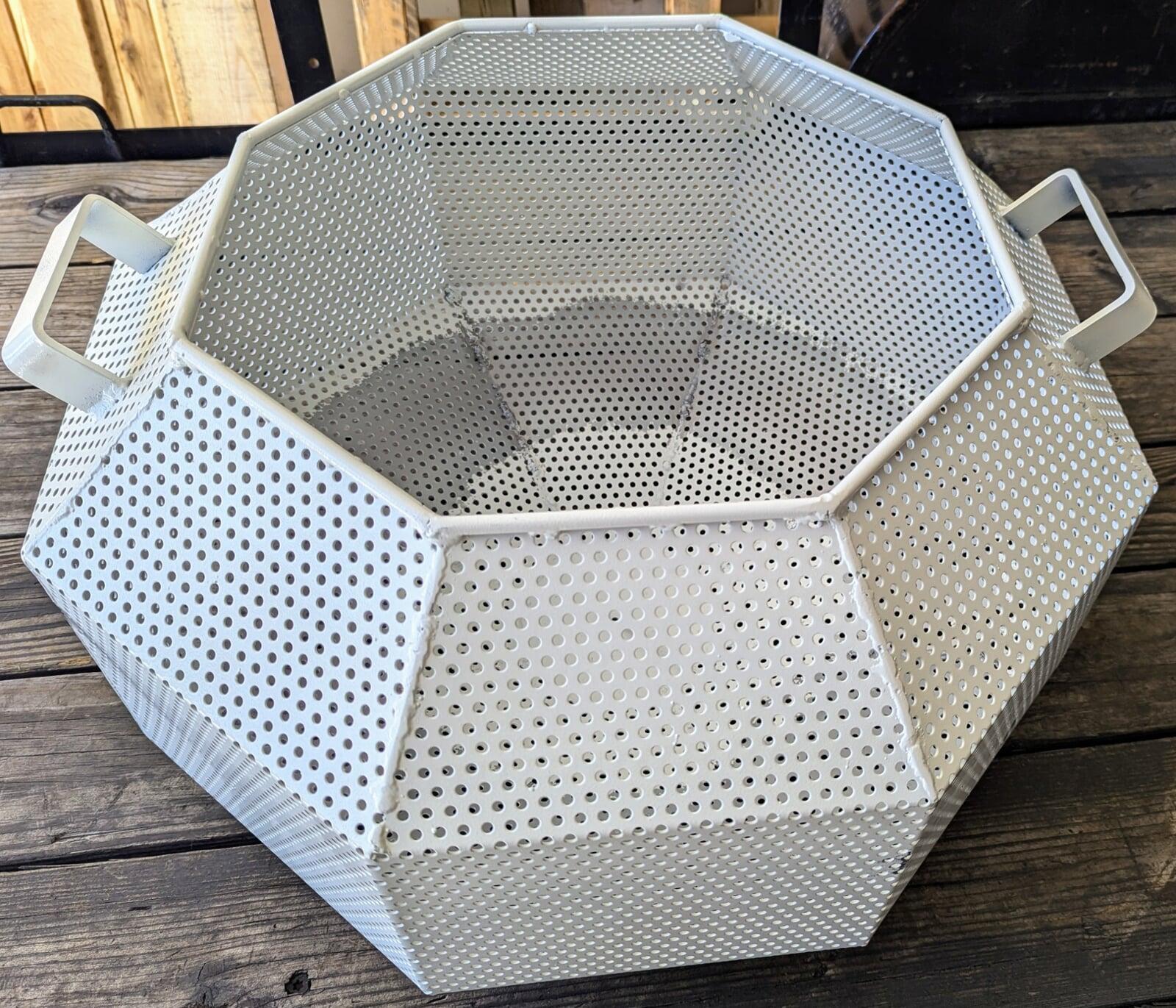

Also known as sand blasting, air blasting utilizes specific air blasting equipment that works by using compressed air to propel various types of abrasive materials onto a surface under high pressure. This typically is used as a way to smooth out a rough surface or even roughen up a smooth surface. With the various sizes of abrasive you can use with air blasting equipment, you can achieve numerous rough or smooth results. Some materials used as an abrasive within our sandblasting equipment include metal shot/grit, aluminum oxide, glass bead, engineered abrasive compounds, starches and baking soda, and sometimes even crushed nut shells.

Air Blasting Applications

Given the wide variety of abrasive materials used with air blasting, it’s no surprise that the variety of applications you can use with sand blasting is just as wide. This is one of the most efficient ways to clean surfaces, so many industries typically use air blasting equipment in a variety of processes, including rust and paint removal, tool and small parts cleaning, street cleaning, and much more.

For more information, or if you have any comments, questions, or concerns on the complete inventory of air blasting equipment that we offer, get in touch with us today. We’re here to connect you with the perfect sand blasting machines for you.