Centrifugal Blasting

Using a centrifugal wheel to propel the media is airless blasting

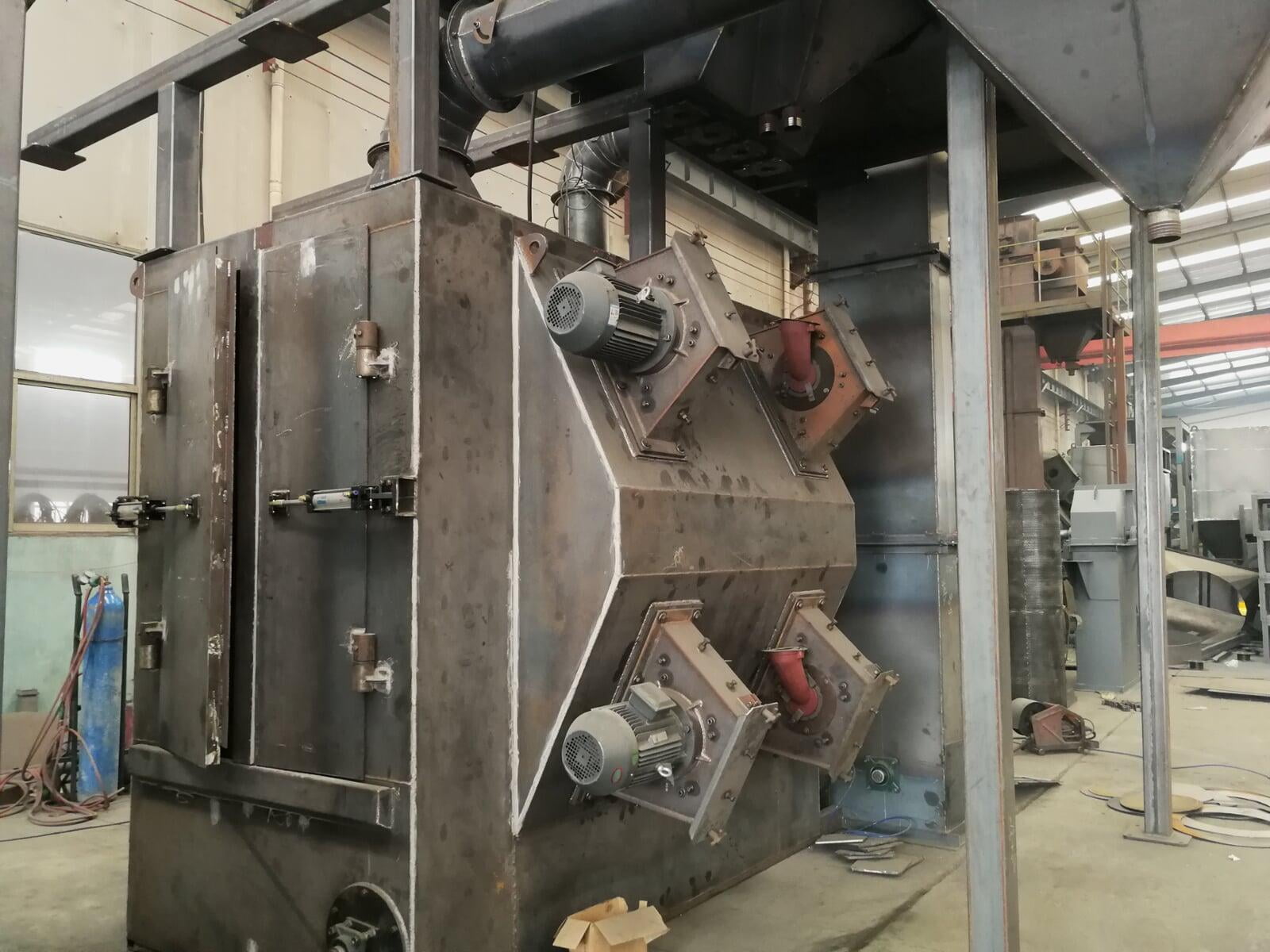

Automatic blast cleaning and shot peening machines can affect surface treatment operations on workloads of almost any nature. Operation of the centrifugal blasting equipment is straightforward and does not require special training.

To keep our machines running well, we ensure the machine-cleaning process is extremely easy and economical. In fact, they represent the best energy, time and labor saving technique. Piece handling may occur by means of revolving table – tumble conveyor – overhead (hanger) conveyor – roller conveyor, flat belt conveyor, and other work transport systems.

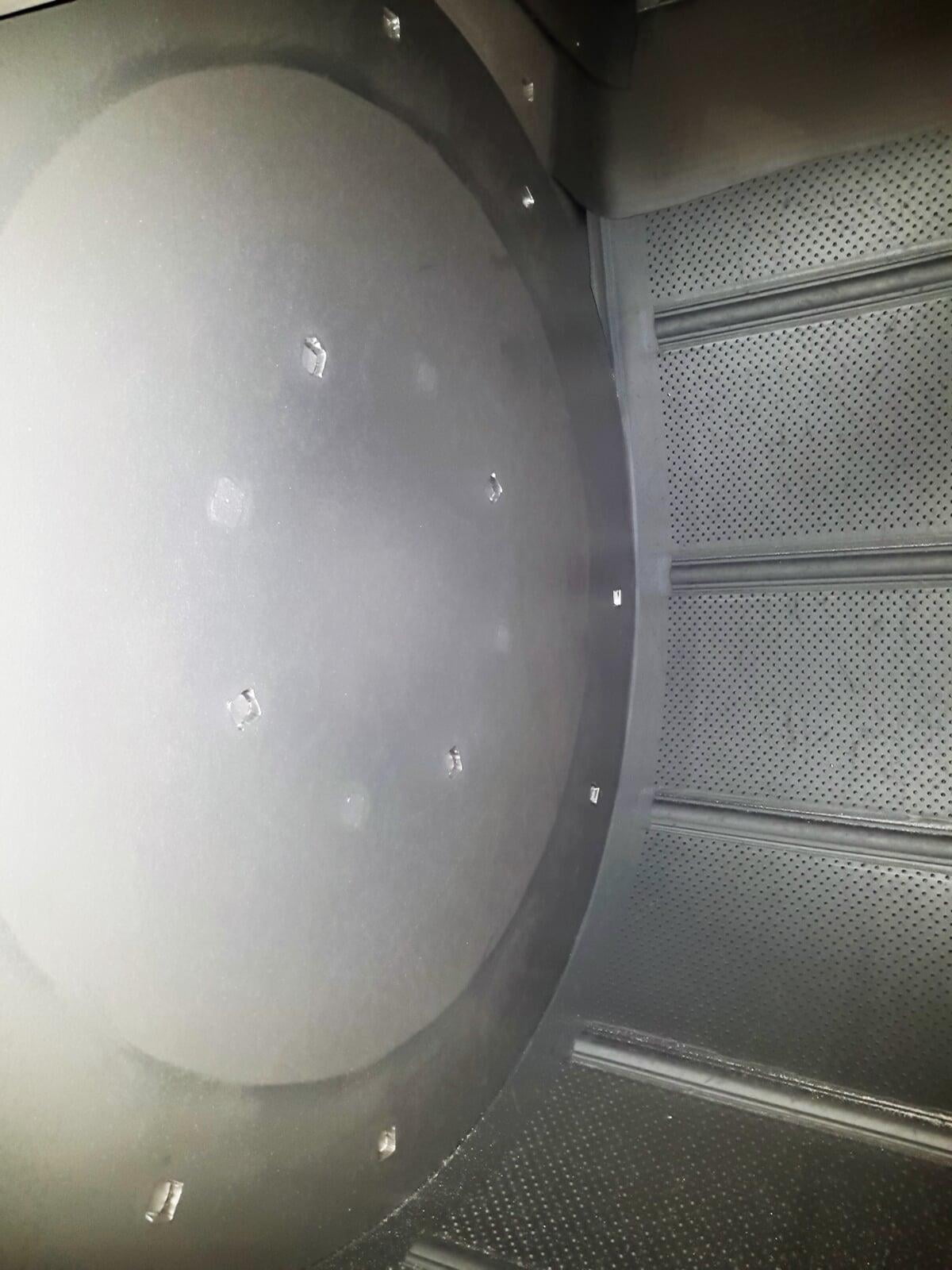

The blastwheel is the heart of airless shot blast cleaning equipment. They are highly efficient and dynamically balanced for consistent performance. Centrifugal blasting provides a means by which the media is propelled to the substrate by introducing many fine grains into the path of a wheel, which propels these grains onto the surface of any item you’re looking to treat. Airless blasting or wheelblasting is many times more efficient than air blasting!

The actual blast cleaning or shot peening process is conducted completely automatically. Workloads are initially introduced into the blasting machine. One or more rapidly rotating centrifugal wheels bombard each workload with tremendous amounts of media grains representing an enormous number of impacts.

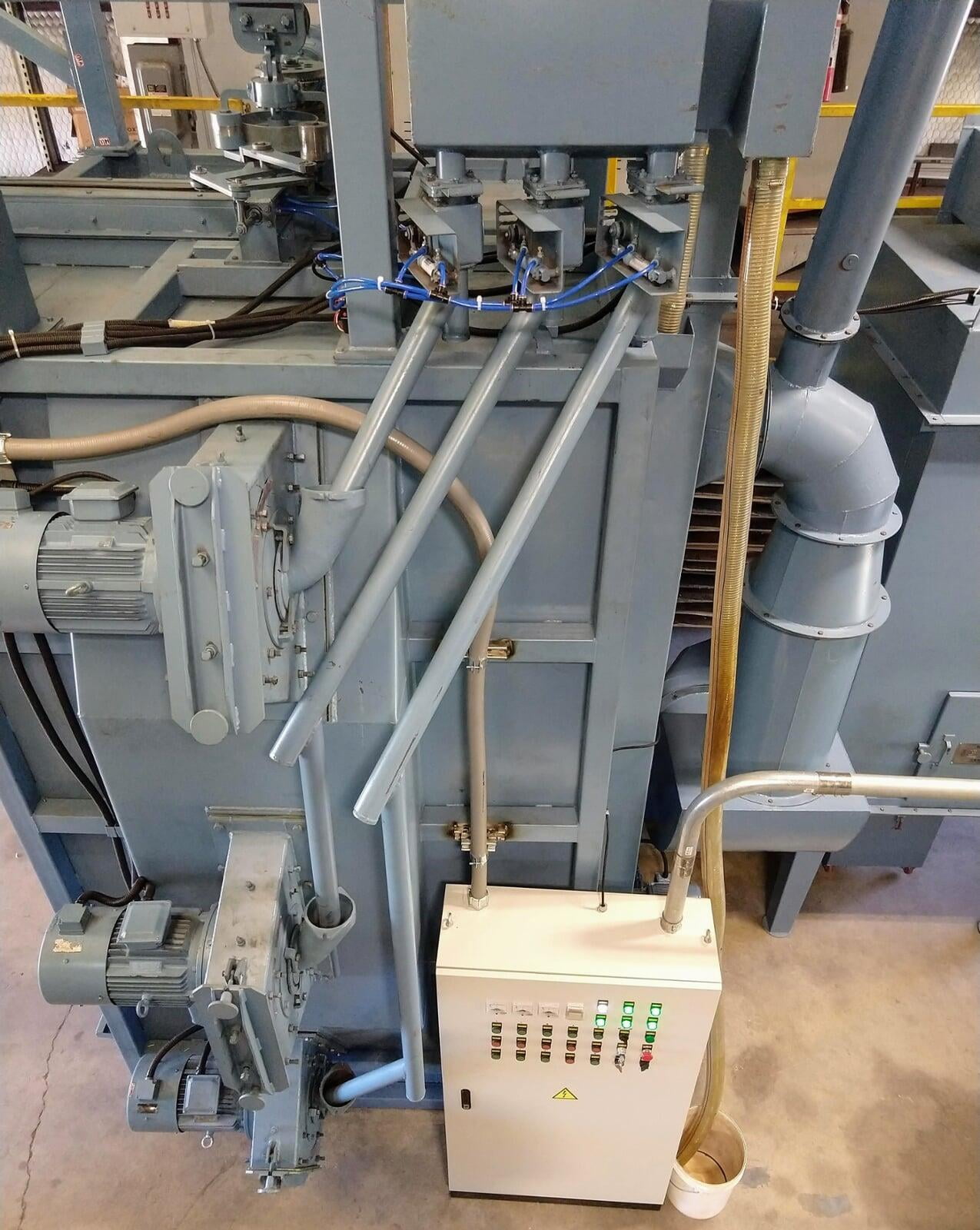

Our centrifugal blasting machines are designed with the operator in mind, able to continue normal operation without requiring constant surveillance. In general, the activities of the operator are mainly limited to loading and unloading although we do provide equipment with fully automated or partially automated loading and unloading systems.

The media can vary from steel, stainless steel, chilled cast iron, non-ferrous metals, ceramic beads, plastic, and others and it is selected in strict conjunction with the application and the required results. We can assist with choosing the proper media material, shape, size, and velocity to properly treat the surface of your materials. For more information on the shot blasting machines we can provide you with, contact us today.